The Journey to Find Cost Efficient Aluminium Rapid Parts Continued - Part Five

It has been quite some time since the last time I put up the

blog. This is mainly down to us being

really busy utilising this new process.

At the end of my last blog, I just received back the first

cast parts having used rapid prototyped master parts in the sand casting

process. I finished off by saying that I

needed to check the parts physical dimensions and compare them to the CAD. Unfortunately we don't have any laser

scanning / CMM here at our facility, but using calibrated callipers (easily

accurate to .05of a mm) I set about measuring the part.

Overall I was very pleased with the results. The part came back with a very good

tolerance. Based on a rage of

measurements made between 60mm to 100mm,

they all came back being slightly larger by an average of 0.5mm. I must be

clear that this is clearly not an accurate representation of the accuracy of

the overall part, however as an initial indication we were very impressed.

Also, I had to remind myself that the design of a cast part

falls into two areas, highly tolerance areas, and lower tolerance areas. In the past when designing aluminium cast

parts I found one of the important elements of the design is to ensure datum's

are provided for our machinists to have a good reference point to work from.

Since the last blog, we have probably made about 12 to 15

different aluminium parts, all of which have been successfully used in the

design and manufacture of prototypes and low volume products.

These two parts came back really well, and as you can see

have very little flaws in the cosmetic appearance. You can see the split line in the left hand

part, but that can't really be avoided given the geometry.

This next photo shows how we post machined the areas that

needed to have a high level of tolerance.

So now that we have done this process with quite a few

parts, I am finding that it really gives us a competitive advantage over a lot

of other companies that use more traditional manufacturing processes for low

volume aluminium parts. Now we know

which days of the week the foundry pour aluminium, we can have the parts from

CAD to being back in our workshop within 2 days, but 3 days is a little more

relaxed for the foundry.

A good example of how useful this can be is during the

product development process. We can now

have parts in aluminium much earlier on in the design process, allowing our

customers to have a much better idea of how their product looks and feels as

well as physically performs.

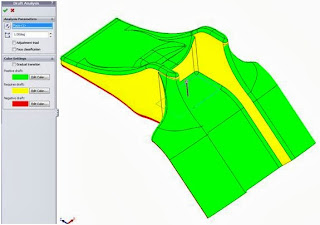

My next plan for this project is to see if I can find anyone

out there who can help me with developing an add on to Solidworks so we can

develop a design checker, specifically for the rapid prototyping / sand casting

process. I was thinking of having quite

a few inputs such as rapid prototyper accuracy, type of aluminium used, even

down to inputting data from previous cast parts to the add on can accurately

predict the shrinkage.

Now clearly this is a lot of work, but it would be great to

develop a free add on for anyone to use. Please di get in touch if you can help in any way, or indeed would like this add on once it is developed!