The Journey to Find Cost Efficient Aluminium Rapid Parts Continued - Part Six

So I got into the office early

this morning, to find an urgent job that needed an aluminium part!

We did the CAD quickly, sent it to

our Uprint 3D printer and I have just arrived back from the foundry with 5

castings! To some it might not sound like much, but for us, managing to

go from concept to aluminium parts in less than 12 hours is fantastic.

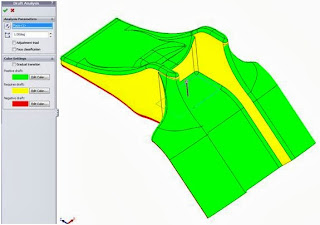

Here is a screen shot of the part in Solidworks.

So after doing the initial CAD I used the Solidworks tools to check the draft angles to make sure the foundry would be OK casting the part without having to rework any of the plastic master.

Here is a screen shot mid way through checking.

Using the scaling tool, I added 3%

to its size and then saved it as an STL ready for the printer.

The UPrint 3D printer took 2 hours

to print the part, and I jumped in the car and dropped it off at the foundry.

Mid afternoon I got a call to say

they were ready for collection.

For those of you out there use to

working with castings, it will look quite good. Those of you not so used

to seeing a raw casting it looks very rough around the edges. Because it

was such a quick job the foundry have not trimmed off the flashing (thin parts

of aluminium that seeps into the split line of the sand mould).

So I will be spending the rest of Friday afternoon filing back the flashing. First thing Monday morning the

parts can be heat treated so they can be a fully structural part.

Its quite an exciting process, and

its great to know it can be done...

No comments:

Post a Comment

Note: only a member of this blog may post a comment.