Over the weekend I was thinking about the parts that we get printed here at work in ABS which are then sent to the sand

casting foundry to get the parts back all in the same day.

I was trying to work out what would make the process

quicker, and also lower cost.

Up to now, I have been printing the parts out and then the

foundry adds in gates, risers and sprues etc to allow the aluminium to enter

the parts at the correct location.

.

Now that I have done this a few times, I was thinking about

sending my next parts to the foundry already with the gates etc on the part, therefore

very low preparation required by the foundry and ultimately saving cost and

time!

First I thought of adding the gates etc into the CAD model and have the part printed ready to go, but then I realised this would take up my time doing the CAD and also use up our precious material for the printer... and the printer would take longer to print.

Then I remembered, a year or so ago I discovered a thermoplastic called Polymorph. It comes in small grains (about the size of rice) and you pour it into boiling water. Within a few seconds it goes clear, then after draining the water out, you have about 2 mins of working time to shape it into whatever shape you need. When it cools, it is rock hard.

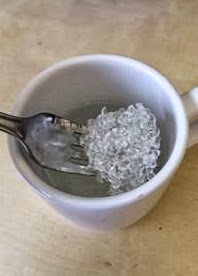

Here is a picture of what's needed. (Cup of boiling

water, printed part and Polymorph)

|

And here it is about 30 seconds after being in the water

(you know it is ready when its gone completely clear)

This next photo shows my first attempt that's not exactly perfect for casting, but you can see what I am trying to do.

This photo shows the part now the polymorph has cooled.

Now the polymorph is hard, you can see what I am trying to

do, essentially to give the foundry a rapid prototyped part ready to be put in

the sand.

It's just an idea I had, so if anyone has any thoughts and ideas I would really appreciate the help & feedback.

No comments:

Post a Comment

Note: only a member of this blog may post a comment.